Con lăn sưởi ấm là gì? Chức năng của nó là gì?

In modern industrial production, temperature control is one of the key factors to ensure product quality and production efficiency. As an important temperature control device, Heating Roller is widely used in plastics, printing, textile, papermaking, metal processing and other industries.

So, what is a Heating Roller? What is its function? This article will explore this in depth.

What is a Heating Roller?

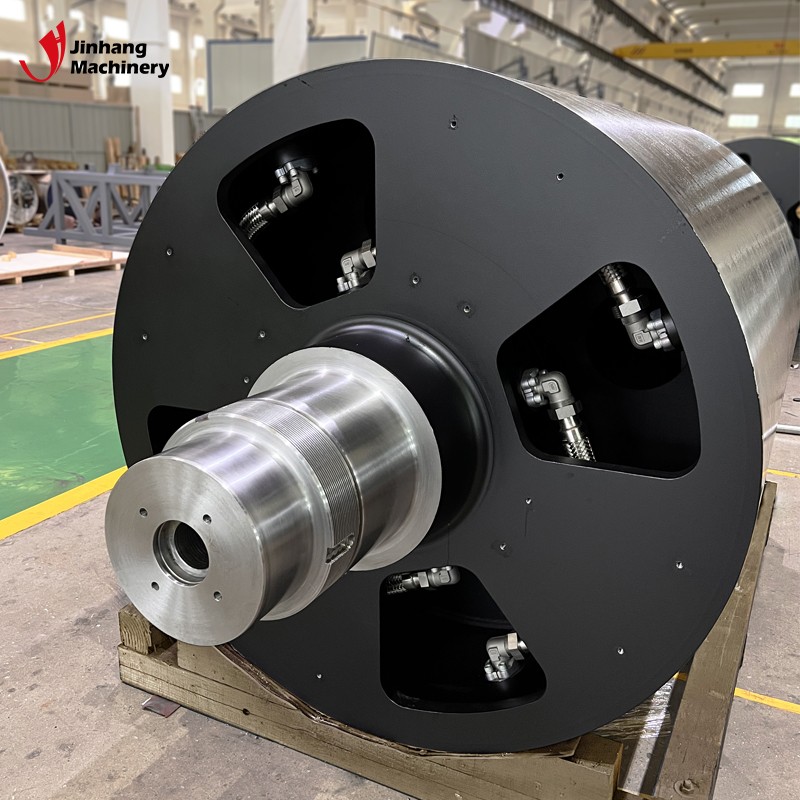

A Heating Roller is a device that generates heat through an internal heating device and transfers the heat to the roller surface to heat and adjust the temperature of the processed material. The interior of the Heating Roller is usually equipped with an electric heating element or a hot oil circulation system, which conducts heat to the roller surface through the heating element or hot oil to reach the required temperature.

What is the working principle of the Heating Roller?

The working principle of the Heating Roller is mainly based on heat conduction and convection heating. The internal heating element or hot oil transfers heat to the roller surface through heat conduction, and then transfers heat to the material through the contact between the roller surface and the processed material, thereby achieving the purpose of heating and adjusting the temperature.

1. Heat conduction heating:

Heat conduction is the main heating method of the Heating Roller. The internal electric heating element or hot oil conducts heat to the roller surface by directly contacting the inner wall of the roller. When the roller surface contacts the material, the heat is transferred to the material through heat conduction, causing its temperature to rise. This heating method is highly efficient and can quickly transfer heat to the material, making it suitable for processes that require rapid heating.

2. Convection heating:

Convection heating is to heat the roller surface by taking away heat through the flow of hot oil inside the roller. The hot oil circulates inside the roller, is heated by the heating system, and then transfers heat to the roller surface by convection. Convection heating can keep the temperature of the roller surface stable and is suitable for processes with long-term continuous production.

What is the role of the heating roller?

The heating roller has many important functions in industrial production: improving the processing performance of materials, controlling the dimensional accuracy of materials, improving production efficiency, and ensuring product quality.

1. Improving the processing performance of materials:

In industries such as plastics, rubber and textiles, the processing performance of materials is often closely related to their temperature. The processing performance of materials can be improved by heating the heating roller. For example, in the plastic extrusion process, the Heating Roller can heat the plastic melt to reduce its viscosity and increase its fluidity, which is convenient for molding and processing. In the textile industry, the Heating Roller can heat fibers and fabrics to enhance their softness and ductility, which is convenient for subsequent processing and handling.

2. Control the dimensional accuracy of materials:

In many industrial production processes, the dimensional accuracy of materials is crucial. Through the precise heating of the Heating Roller, the expansion and contraction of the material can be controlled to ensure its dimensional accuracy. For example, in metal processing, the Heating Roller can evenly heat the metal sheet to prevent its deformation and dimensional deviation caused by uneven temperature. In the papermaking industry, the Heating Roller can heat the paper, control its humidity and dimensional stability, and ensure the quality and dimensional accuracy of the paper.

3. Improve production efficiency:

Through the rapid heating of the Heating Roller, the processing speed of the material can be accelerated and the production efficiency can be improved. On a high-output production line, the Heating Roller can quickly heat the material to the required temperature and shorten the heating time, thereby improving production speed and efficiency. For example, in the printing industry, the Heating Roller can quickly heat the printed paper, making it dry faster and improving the printing speed and efficiency.

4. Ensure product quality:

The temperature control ability of the Heating Roller has a direct impact on product quality. During the production process, the temperature change of the material will affect its physical and chemical properties. Through the precise heating of the Heating Roller, the dimensional accuracy, surface quality and mechanical properties of the product can be ensured. For example, in the production of plastic film, the Heating Roller can evenly heat the film to avoid wrinkling and deformation of the film due to uneven temperature, ensuring the quality and performance of the film.

What are the application areas of the Heating Roller?

The application areas of the Heating Roller are: plastic and rubber industry, printing industry, textile industry, papermaking industry, metal processing industry.

1. Plastic and rubber industry:

In the plastic and rubber industry, the Heating Roller is an important heating equipment. Plastic extrusion, film production, sheet forming and other processes all require the Heating Roller to heat the material to ensure its fluidity and processing performance. For example, in the plastic film production line, the Heating Roller can heat the plastic film to the required temperature for easy molding and processing.

2. Printing Industry:

In the printing industry, the Heating Roller is used to heat the printing paper and ink to ensure its quick drying and adhesion. For example, in thermal transfer printing, the Heating Roller can heat the transfer paper to make the ink dry quickly and improve the printing speed and efficiency. In offset printing, the Heating Roller can heat the paper to prevent the paper from deforming and wrinkling due to humidity changes.

3. Textile Industry:

In the textile industry, the Heating Roller is used for heating and shaping of fibers and fabrics. In the process of fiber stretching and fabric finishing, the fibers and fabrics need to be heated by the Heating Roller to improve their softness and ductility for subsequent processing and handling. For example, in the process of polyester fiber stretching, the Heating Roller can heat the fiber to the required temperature to improve the stretching effect and product quality.

4. Papermaking Industry:

In the papermaking industry, the Heating Roller is used for heating and humidity control in the paper production process. After the pulp is dried by the dryer, it needs to be heated to the appropriate temperature by the Heating Roller to ensure the flatness and quality of the paper. The Heating Roller can also adjust the humidity of the paper to avoid deformation and quality problems caused by temperature and humidity changes.

5. Metal processing industry:

In the metal processing industry, the Heating Roller is used for heating and annealing of metal sheets and coils. In the hot rolling and cold rolling processes, the metal sheets need to be heated by the Heating Roller after high-temperature treatment to obtain the required mechanical properties and surface quality. The Heating Roller can evenly heat the metal sheets to prevent deformation and oxidation caused by uneven temperature, and ensure the quality and performance of the products.

Conclusion

As an indispensable and important equipment in industrial production, the Heating Roller has been widely used in many industries due to its excellent heating performance. The Heating Roller can effectively improve the processing performance of materials, control the dimensional accuracy of materials, improve production efficiency, ensure product quality, and extend the service life of equipment.

Whether in the plastics, printing, textiles, papermaking or metal processing industries, the Heating Roller provides reliable and efficient solutions for industrial production.