Con lăn mạ crom công nghiệp có bền không?

Tuổi thọ của con lăn mạ crom là bao lâu?Khi xem xét độ bền của con lăn mạ crôm, tuổi thọ sử dụng là một chỉ số tham chiếu quan trọng. Nhìn chung, con lăn mạ crôm chất lượng cao có thể được sử dụng trong môi trường công nghiệp khắc nghiệt trong nhiều năm hoặc thậm chí hơn mười năm. Độ dài tuổi thọ sử dụng của nó không chỉ phụ thuộc vào độ dày và chất lượng của lớp mạ crôm mà còn phụ thuộc vào nhiều yếu tố như môi trường sử dụng, điều kiện vận hành và bảo dưỡng.Xét về hiệu suất chi phí, mặc dù chi phí sản xuất con lăn mạ crôm tương đối cao, nhưng độ bền tuyệt vời và chi phí bảo trì thấp mang lại lợi thế kinh tế rõ ràng khi sử dụng lâu dài. So với con lăn làm bằng vật liệu khác, con lăn mạ crôm có thể chịu được các thử nghiệm khắc nghiệt trong sản xuất công nghiệp tốt hơn, giảm tần suất thay thế thiết bị và bảo trì thời gian chết, do đó cải thiện hiệu quả sản xuất và giảm chi phí sản xuất.

Qua thảo luận sâu về độ bền của con lăn mạ crôm công nghiệp, chúng ta có thể kết luận rằng con lăn mạ crôm có độ bền rất cao. Khả năng chống mài mòn và chống ăn mòn tuyệt vời của nó cho phép nó hoạt động tốt trong nhiều môi trường công nghiệp khắc nghiệt khác nhau và có thể hoạt động ổn định trong thời gian dài. Tuy nhiên, để phát huy hết độ bền của con lăn mạ crôm, các doanh nghiệp phải chú ý đến các thông số vận hành và bảo dưỡng hàng ngày trong quá trình sử dụng để đảm bảo thiết bị luôn trong tình trạng hoạt động tốt.

Cuộn công nghiệp tùy chỉnh theo nhu cầu của bạn – JH Machinery

Tại JH Machinery, chúng tôi cung cấp các loại trục công nghiệp tùy chỉnh được thiết kế để đáp ứng các ứng dụng khắt khe nhất. Lựa chọn của chúng tôi bao gồm các trục gương, trục làm mát và trục mạ crôm, tất cả đều được sản xuất bằng vật liệu chính xác và chất lượng cao. Là một nhà sản xuất giàu kinh nghiệm, chúng tôi cung cấp các tùy chọn giá linh hoạt và nhiều chương trình khuyến mãi để đảm bảo bạn nhận được ưu đãi tốt nhất. Liên hệ với chúng tôi để nhận báo giá cá nhân và tìm hiểu thêm về các tùy chọn giá thấp và các giải pháp tùy chỉnh của chúng tôi.

The main function of the chrome plating layer is to improve the surface properties of the roller, especially the wear resistance and corrosion resistance. Chromium is a metal element with extremely high hardness, and its hardness can reach 600 to 1000 Vickers hardness (HV), which makes the chrome plating layer have very high wear resistance. In addition, chrome also has excellent anti-oxidation and corrosion resistance, which can effectively resist the erosion of chemical media and extend the service life of the roller.

Is the industrial chrome plated roller durable?

The wear resistance of chrome plated roller

The durability of chrome plated roller is first reflected in its wear resistance. In industrial production, chrome plated rollers usually need to work under high pressure, high speed and high friction conditions. For example, in processes such as steel plate rolling and plastic film production, there will be strong friction between the roller surface and the processed material. If the roller surface material is not wear-resistant, scratches, dents and other wear phenomena are prone to occur, which will affect the product quality.

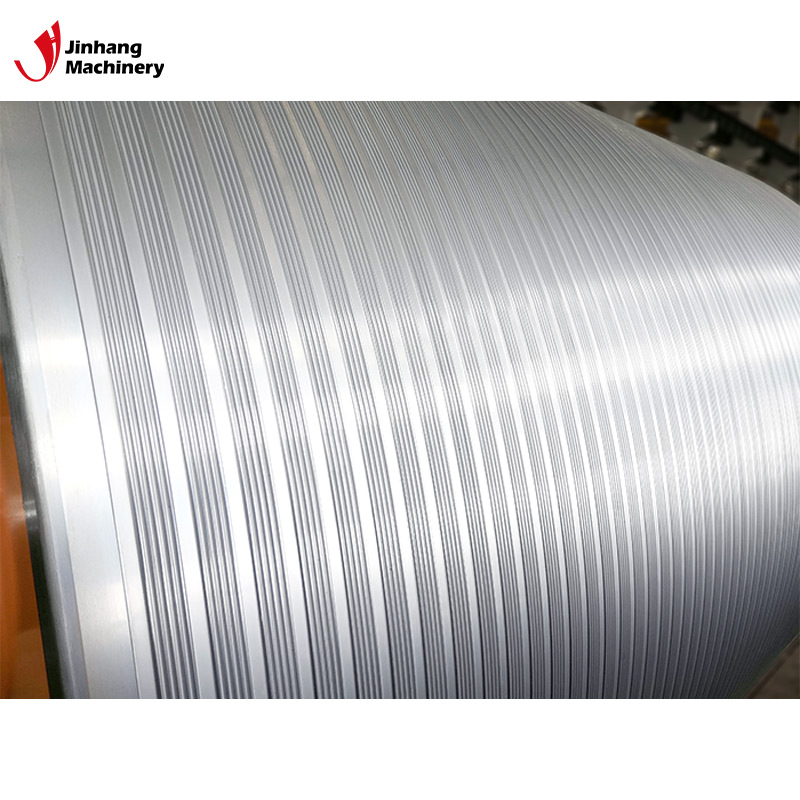

The high hardness of the chrome plating layer enables it to maintain a good surface state when facing high-intensity friction, and it is not easy to be worn or scratched. Even after long-term use, the surface of the chrome plated roller can still remain smooth and uniform. This excellent wear resistance makes chrome plated rollers extremely durable in industrial production.

However, although the chrome plating layer has high hardness, its toughness is relatively low. If it is subjected to strong impact or excessive stress, the chrome plating layer may peel off or crack. Therefore, when using chrome plated rollers, operators need to pay attention to avoid excessive mechanical impact and keep the equipment running smoothly.

Corrosion resistance of chrome plated rollers

In many industrial environments, equipment needs to face the erosion of various chemicals, such as acids, alkalis, and salt solutions. If the roller material does not have good corrosion resistance, it may cause surface corrosion, thus affecting the normal use of the equipment.

The chrome plating layer has excellent corrosion resistance, especially in acidic and alkaline environments. Chromium easily forms a dense chromium oxide film in the air, which can effectively block the intrusion of oxygen and moisture and prevent oxidation reactions of the metal substrate. In addition, chromium also has strong corrosion resistance to most acidic media and can remain stable for a long time in harsh chemical environments.

However, the corrosion resistance of the chrome plating layer is not absolute. In strong acid and alkali environments, especially in highly corrosive media such as hydrofluoric acid and hot concentrated sulfuric acid, the chrome plating layer may still be corroded. Therefore, when choosing the use environment of the chrome plated roller, the type and concentration of the chemical medium must be fully evaluated to ensure that the chrome plated roller can operate stably for a long time.

What is the impact of the manufacturing process on the durability of the chrome plated roller?

The manufacturing process of the chrome plated roller directly affects its durability, especially in terms of the quality and thickness of the chrome plating layer. The chrome plating process usually includes three main steps: pre-treatment, chrome plating and post-treatment. In the pre-treatment stage, the surface of the roller core needs to be cleaned, degreased, pickled and other treatments to ensure that the surface is free of pollutants and achieve the ideal roughness. The quality of the pre-treatment is directly related to the adhesion and uniformity of the chrome plating layer.

The chrome plating stage is the core of the entire process. The chromium ions are deposited on the surface of the roller core through the electroplating process to form a uniform chrome plating layer. In this process, the process parameters such as the ratio of the plating solution, temperature, current density, and time need to be strictly controlled to ensure that the thickness of the chrome plated layer is uniform and the structure is dense. The more uniform and dense the chrome plated layer is, the stronger its wear resistance and corrosion resistance will be.

In the post-processing stage, the chrome plated roller usually needs to be polished, passivated, and other treatments to further improve the surface finish and corrosion resistance. After fine post-processing, the chrome plated roller is not only smooth and flat, but also can effectively prevent further corrosion of the chrome plated layer by the external environment.

However, the complexity of the chrome plating process also means that its quality is easily affected by many factors, such as operational errors, electroplating solution contamination, and equipment aging. Therefore, strict quality control measures are required in the production process to ensure that each chrome plated roller can achieve the desired durability.

What is the impact of the use environment and operation on the durability of chrome plated rollers?

Although chrome plated rollers are designed and manufactured with durability as the goal, their actual service life is also affected by the use environment and operating conditions. In high temperature, high humidity, and strong acid and alkali environments, the durability of chrome plated rollers may be challenged to a certain extent. For example, in a high temperature environment, the hardness of the chrome plating layer may decrease, which in turn affects its wear resistance; in a high humidity environment, the oxidation resistance of the chrome plating layer may weaken, thereby increasing the risk of corrosion.

In addition, improper operation is also an important factor affecting the durability of chrome plated rollers. For example, during use, if the roller surface is hit or scratched by a hard object, the chrome plating layer may be damaged or even partially peeled off. Once the chrome plating layer is damaged, the substrate is exposed and is extremely susceptible to corrosion and wear, which accelerates the aging of the roller. Therefore, when using chrome plated rollers, operators must follow strict operating procedures to avoid any behavior that may damage the chrome plating layer.

What is the impact of maintenance on the durability of chrome plated rollers?

Reasonable maintenance is the key to extending the service life of chrome plated rollers. Since chrome plated rollers are inevitably affected by various factors during long-term use, regular inspection and maintenance are essential. Common maintenance measures include surface cleaning, anti-corrosion treatment, lubrication, etc. Especially in the case of harsh use environment, it is more necessary to strengthen the maintenance of chrome plated rollers.

In terms of surface cleaning, the use of appropriate cleaning agents and tools can effectively remove dirt and residues on the surface of chrome plated rollers, preventing these impurities from causing further wear or corrosion to the chrome plating layer. At the same time, during long-term deactivation or storage, chrome plated rollers should be treated with anti-rust treatment, such as applying anti-rust oil or using anti-rust agent, to prevent the chrome plating layer from rusting due to environmental factors.

In addition, regular inspections are also key measures to ensure the long-term durability of chrome plated rollers. Through inspections, damage to the chrome plating layer can be discovered in time, and necessary repairs or replacements can be made. For chrome plated rollers that have been worn or corroded, re-chrome plating or replacement should be carried out according to the specific circumstances to avoid greater impact on production.

What is the service life of chrome plated rollers?

When considering the durability of chrome plated rollers, service life is an important reference indicator. Generally, high-quality chrome plated rollers can be used in harsh industrial environments for several years or even more than ten years. The length of its service life depends not only on the thickness and quality of the chrome plating layer, but also on a variety of factors such as the use environment, operating conditions, and maintenance.

From the perspective of cost performance, although the manufacturing cost of chrome plated roller is relatively high, its excellent durability and low maintenance cost give it obvious economic advantages in long-term use. Compared with rollers made of other materials, chrome plated rollers can better withstand the harsh tests in industrial production, reduce the frequency of equipment replacement and downtime maintenance, thereby improving production efficiency and reducing production costs.

Through an in-depth discussion of the durability of industrial chrome plated rollers, we can conclude that chrome plated rollers have very high durability. Its excellent wear resistance and corrosion resistance enable it to perform well in various harsh industrial environments and can operate stably for a long time. However, in order to give full play to the durability of chrome plated rollers, enterprises must pay attention to operating specifications and daily maintenance during use to ensure that the equipment is always in good working condition.

Industrial Rolls Customized for Your Needs – JH Machinery

At JH Machinery, we provide customized industrial rolls designed to meet the most demanding applications. Our selection includes mirror rolls, cooling rolls, and electroplated chrome rolls, all manufactured with precision and high-quality materials. As an experienced manufacturer, we offer flexible pricing options and a range of promotions to ensure you get the best deal. Contact us for a personalized quote and to learn more about our low-price options and customized solutions.

Ngoài ra, kiểm tra định kỳ cũng là biện pháp then chốt để đảm bảo độ bền lâu dài của con lăn mạ crôm. Thông qua kiểm tra, có thể phát hiện kịp thời hư hỏng của lớp mạ crôm và có thể tiến hành sửa chữa hoặc thay thế cần thiết. Đối với con lăn mạ crôm đã bị mòn hoặc bị ăn mòn, cần mạ crôm lại hoặc thay thế theo các trường hợp cụ thể để tránh ảnh hưởng lớn hơn đến sản xuất.